how to use tensile testing machine|tensile testing machine pdf : purchasing The parameters most often evaluated using the tensile test machine are modulus of elasticity, yield strength, elongation and tensile strength. Some important features and factors include: Load Cell: An instrument that accurately measures the .

Resultado da 15 de fev. de 2022 · Fatal Model afirma que modelo da empresa traz mais segurança para as acompanhantes (Foto: Getty Images) — Foto: GQ. O .

{plog:ftitle_list}

Always consult your healthcare provider to ensure the information displayed on this page applies to your personal circumstances. Some side effects may not be . Ver mais

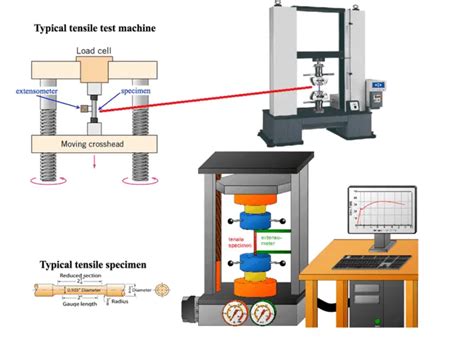

typical tensile test machine

Step 1: Setting Up the Universal Testing Machine. Get your UTM ready for action—here is what you do: Power up the machine. Calibrate the Machine: Follow the manufacturer's guidelines to go through the procedure of calibrating a load cell. This allows the force measurement . Tensile testing machines operate by exerting a tensile (pulling) force on a material sample until it fails. The process begins with the preparation of a test specimen, which is typically a standardized shape and size to ensure .

tensile testing machine procedure

Tensile test machines, also known as tensile testers, are universal testing machines specially configured to evaluate the tensile strength of specimens. Our tensile testers will measure characteristics such as ultimate tensile strength, .

A Universal Testing Machine (UTM), also known as a tensile testing machine/tester, is an electromechanical testing system that applies a tensile force to raw materials or components to test for both tensile and compressive .

In a simple tensile test, a sample is typically pulled to its breaking point to determine the ultimate tensile strength of the material. The amount of force (F) applied to the sample and the elongation (∆L) of the sample are measured .

The parameters most often evaluated using the tensile test machine are modulus of elasticity, yield strength, elongation and tensile strength. Some important features and factors include: Load Cell: An instrument that accurately measures the .

Researchers use tensile testing machines to study the behavior of novel materials, such as high-performance concrete and advanced composites, guiding their development for specific applications. Pacorr’s tensile testing machines provide accurate and reliable test results, supporting the construction industry’s efforts to build safer and . Connect the specimen to the tensile testing machine. Once the specimen is threaded to the bottom collet, place the other half jog the machine up to be able to thread the top to secure the specimen inside the unit. Install the extensometer on the specimen; Make sure there is some wiggle room in the specimen to record the best data, to avoid the .

Measurement of Load and Displacement. All testing systems have some sort of “loading train”, of which the sample forms a part.This “train” can be relatively complex - for example, it might involve a rotating worm drive (screw thread) somewhere, with the force transmitted to a cross-head and thence via a gripping system to the sample and then to a base .

tensile testing machine price list

Our materials testing machines are used in R&D and for quality assurance in more than 20 industries. . Whether tensile test, compression test or flexure tests, function tests or standard tests, texture analysis or fatigue testing: with our product groups we offer testing solutions for test methods in R&D, as well as for quality assurance in . Although the two groups of test specimens—finished products and raw materials—are handled in different ways in their lifecycle, there are universal practices applicable to performing an accurate tensile test on either. In fact, the equipment used is often termed a universal testing machine (UTM), being capable of a variety of test types .Universal Testing Systems for Tensile, Compression, and Flexure Testing . The 6800 series Universal Testing Machines are designed to perform tensile, compression, flex, peel, puncture, friction, shear tests, and more. The systems are compatible with hundreds of grips and fixtures found in Instron’s expansive accessories catalog, with .Typical lectromechanical Universal Testing Machine Test fixture for three point flex test. A universal testing machine (UTM), also known as a universal tester, [1] universal tensile machine, materials testing machine, materials test frame, is used to test the tensile strength (pulling) and compressive strength (pushing), flexural strength, bending, shear, hardness, and .

Operators can use the handset in the frame mounted position or removed from its dock. • Dual Test Space Design on Select Frames The DX and HDX frames are designed for tension, compression, bend/flex, and shear testing without needing to remove application specific fixtures from the compression test space in order to perform tensile tests.Most materials that are tested using a Tensile or Universal Testing Machine, will show to begin with a linear relationship between the applied force (stress) and the elongation (strain) of the sample tested. In this linear region of the test, the line obeys the relationship that is defined as “Hooke’s Law” where the ratio of stress to .A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile strength .

You're about to enter the world of tensile testing, using a Universal Testing Machine. Trust me, it's an exciting journey to understand the material strengths, flexibility, and general behavior under stress. But, prior to mastering one, let us first go step-by-step to make sure that you are well-prepped to conduct a tensile test like a real pro.

Tensile testing with strain measurement techniques that can determine critical material properties including elastic modulus, tensile strength, elongation at break, and Poisson’s ratio. . Equipment Monitoring ; Software & Monitoring Solution Finder Search by Test Material, Test Type, or Test Standard to find relevant products fast. .

Since this machine can be used on a variety of material, so the test procedures will be different. Here, we introduce the tensile test procedures for the tensile testing process. 1) Prepare specimens. Before starting the test . Introduction Importance of Tensile Testing Machines in Material Analysis Tensile testing machines play a vital role in evaluating the strength and durability of materials across industries. Whether it’s determining the tensile strength of metals, plastics, textiles, or other materials, these machines provide essential data for product development and quality control. .A UTM or universal testing machine is referred to as universal because it can be used to perform a variety of static tests, including tensile tests and compression tests, as well as flexure tests, peel tests, tear tests and other mechanical tests. It can run a wide variety of standard-compliant tests on an even larger number or materials for many different applications in essentially every .The computerized tensile testing machine will be used to produce stress versus strain plots for several different specimens having rectangular cross sections. The data is used to determine the modulus of elasticity while the specimens are examined for failure characteristics. Information

Tensile testing is a key part of basic materials characterization. This video discusses the equipment used when performing a tension test and explains why th. A tensile testing machine, also known as a tensile test machine or a tensile strength tester, is an apparatus used in the mechanical testing of materials. It measures the force required to elongate a specimen to its breaking point, which helps determine material properties like tensile strength, maximum elongation, and reduction in area.

Both the load (stress) and the test piece extension (strain) are measured and from this data an engineering stress/strain curve is constructed, Fig.3.From this curve we can determine: a) the tensile strength, also known as the ultimate tensile strength, the load at failure divided by the original cross sectional area where the ultimate tensile strength (U.T.S.), σ max = P max /A 0, . In this video, we offer quick tips on how to safely use an Instron® universal testing system. For additional safety information, visit https://bit.ly/2lA1n9S.Standard Working Procedure of Tensile Testing Machine. To operate the lab testing instrument efficiently, first of all, take a piece of rubber specimen which you want to test. Now cut the sample in a standard shape says, in a form of a dumbbell. Now clamp the specimen onto the machine by fixing the two ends of the sample on the upper jaw and .These materials testing machines feature a wide measurement range, which allows for precise determination of even low test loads, without the need to convert the testing machine. Low-maintenance, play-free pre-stressed ball screws guarantee accurate long-term operation in the tensile and compression directions.

поточный влагомер нефтепродуктов модель easz1

d) Open an existing test method by clicking on Test and choose which method you want to use. You must use an existing test method, you cannot create one as you go along. For creating a test method, please see the SOP “Creating a Test Method in Bluehill 3”. Step 2: Software Setup . a) Once inside the test method of choice, enter a sample name.

tensile testing machine pdf

tensile testing machine manufacturers

tensile testing machine drawing

No Portal Yaoi, nossa paixão é proporcionar a você o melho.

how to use tensile testing machine|tensile testing machine pdf